When it comes to laboratory processes, ensuring purity and precision is paramount. One of the critical tools used in laboratories for purification and filtration is the solvent filter trap. This device plays an essential role in maintaining the quality of solvents, which is crucial for various experiments and analyses.

The solvent filter trap has become an indispensable part of laboratory workflows, particularly in analytical chemistry, pharmaceuticals, and biotechnology. It serves as a safeguard against impurities that can compromise results and equipment longevity. Understanding its function and applications can greatly enhance laboratory efficiency and accuracy.

In this article, we will delve deep into the world of solvent filter traps, exploring their design, applications, benefits, and maintenance. Whether you're a laboratory technician, scientist, or student, this guide will provide valuable insights into how solvent filter traps can elevate your work processes and ensure consistent quality.

Read also:Discover The Magic Of Temporary Hair Color Spray Blonde A Complete Guide

Table of Contents

- What is a Solvent Filter Trap?

- Types of Solvent Filter Traps

- Applications of Solvent Filter Traps

- Advantages of Using Solvent Filter Traps

- Maintenance Tips for Solvent Filter Traps

- How to Select the Right Solvent Filter Trap

- Common Issues and Troubleshooting

- Environmental Impact of Solvent Filter Traps

- Cost-Effectiveness of Solvent Filter Traps

- Future Trends in Solvent Filter Trap Technology

What is a Solvent Filter Trap?

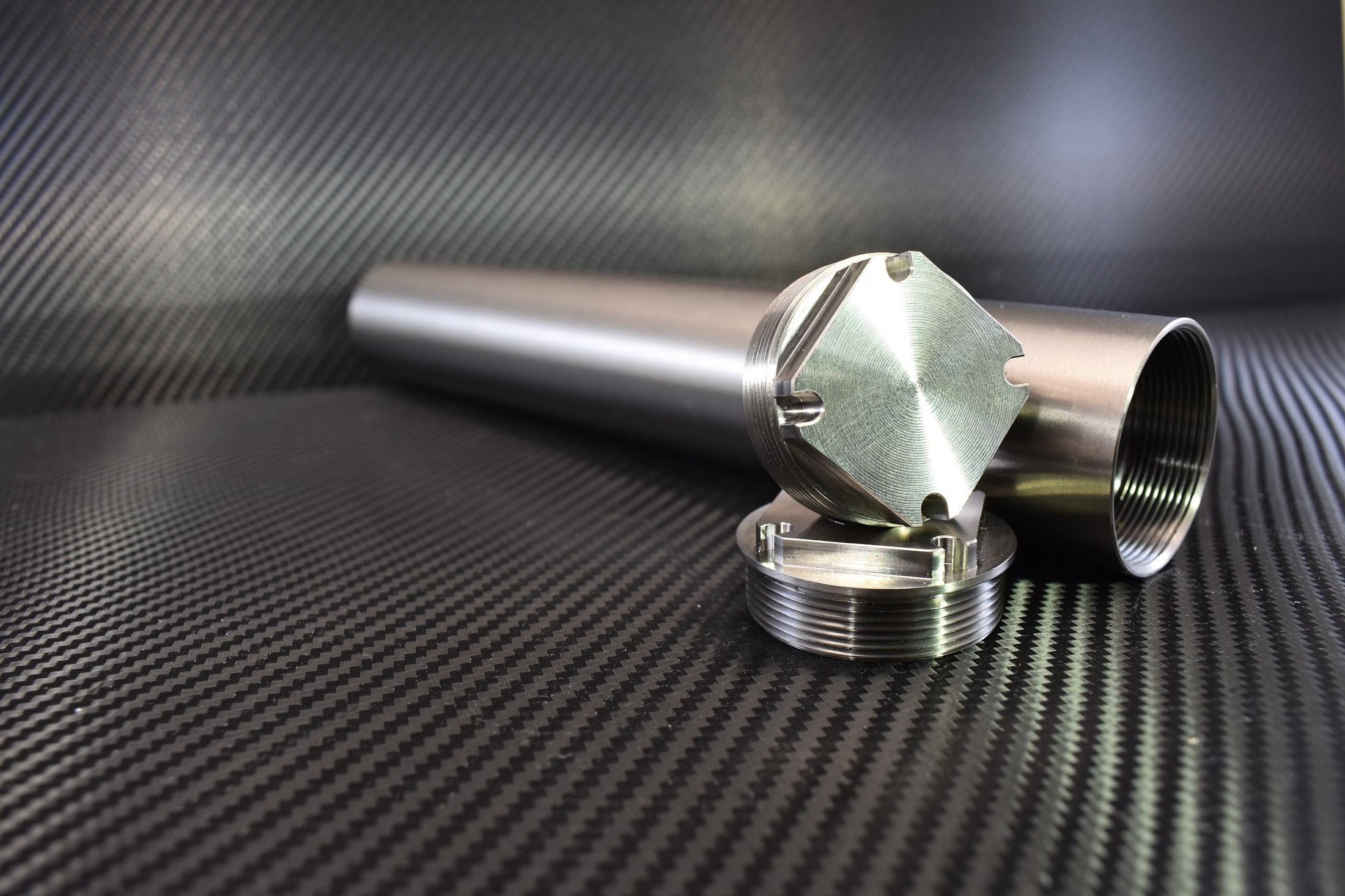

A solvent filter trap is a device used in laboratories to remove impurities, particulates, and contaminants from solvents. These traps are designed to ensure the purity of solvents by filtering out unwanted substances that could interfere with experiments or damage sensitive equipment. They are commonly used in high-performance liquid chromatography (HPLC), gas chromatography (GC), and other analytical techniques where solvent purity is critical.

Key Features of Solvent Filter Traps

- Highly efficient filtration capabilities

- Compatibility with a wide range of solvents

- Robust construction for durability

- Easy installation and maintenance

Solvent filter traps come in various sizes and configurations, allowing users to select the most appropriate option for their specific needs. They are often equipped with microporous membranes that effectively capture particles down to sub-micron levels, ensuring the highest level of solvent purity.

Types of Solvent Filter Traps

There are several types of solvent filter traps available, each designed for specific applications and requirements. Understanding the differences between these types can help in selecting the right trap for your laboratory needs.

1. Disposable Solvent Filter Traps

Disposable solvent filter traps are convenient and cost-effective for laboratories that require frequent changes. They are pre-sterilized and ready to use, reducing the risk of contamination.

2. Reusable Solvent Filter Traps

Reusable solvent filter traps are ideal for laboratories that prioritize sustainability and cost savings. These traps can be cleaned and reused multiple times, making them an eco-friendly option.

Read also:How Many Calories Are In A Starbucks Coffee A Complete Guide

3. Inline Solvent Filter Traps

Inline solvent filter traps are integrated directly into the solvent delivery system, providing continuous filtration without interrupting the workflow. They are commonly used in HPLC systems to protect sensitive components from particulate contamination.

Applications of Solvent Filter Traps

Solvent filter traps are versatile tools with applications across various industries. Here are some of the most common uses:

- Chemical analysis in pharmaceuticals

- Purification processes in biotechnology

- Quality control in manufacturing

- Research and development in academic institutions

Each application requires a specific type of solvent filter trap, tailored to the unique demands of the process. Proper selection ensures optimal performance and reliability.

Advantages of Using Solvent Filter Traps

Implementing solvent filter traps in your laboratory offers numerous benefits:

- Improved solvent purity

- Extended equipment lifespan

- Reduced downtime and maintenance costs

- Enhanced accuracy and reliability of results

By maintaining high levels of solvent purity, laboratories can achieve more consistent and reproducible results, ultimately leading to better decision-making and innovation.

Maintenance Tips for Solvent Filter Traps

Proper maintenance is crucial for ensuring the longevity and effectiveness of solvent filter traps. Here are some tips to keep them in top condition:

- Regularly inspect and replace filters as needed

- Follow manufacturer guidelines for cleaning and sterilization

- Monitor performance and address any issues promptly

- Store traps in a clean, dry environment when not in use

By adhering to these maintenance practices, laboratories can maximize the efficiency and reliability of their solvent filter traps.

How to Select the Right Solvent Filter Trap

Choosing the right solvent filter trap involves considering several factors:

- Compatibility with specific solvents

- Filtration capacity and efficiency

- Size and configuration requirements

- Cost and budget constraints

Consulting with experts or referring to technical specifications can help in making an informed decision. Additionally, considering long-term needs and scalability is important for future-proofing your laboratory setup.

Common Issues and Troubleshooting

Despite their robust design, solvent filter traps may encounter issues over time. Here are some common problems and their solutions:

1. Clogged Filters

Solution: Replace or clean the filters regularly to prevent clogging.

2. Leaks

Solution: Check connections and seals for tightness and integrity.

3. Reduced Flow Rate

Solution: Investigate potential blockages and ensure proper maintenance.

Addressing these issues promptly can prevent further complications and maintain optimal performance.

Environmental Impact of Solvent Filter Traps

Solvent filter traps contribute to environmental sustainability by reducing waste and minimizing the use of harmful chemicals. Reusable traps, in particular, offer a greener alternative to disposable options. Additionally, proper disposal of used filters ensures minimal environmental impact.

Many manufacturers are now focusing on eco-friendly designs and materials, aligning with global efforts to reduce carbon footprints and promote sustainability.

Cost-Effectiveness of Solvent Filter Traps

While initial costs may vary depending on the type and brand of solvent filter trap, the long-term benefits often outweigh the expenses. Reusable traps, for example, can significantly reduce operational costs over time. Moreover, the improved efficiency and reduced downtime contribute to overall cost savings.

Investing in high-quality solvent filter traps can lead to better resource management and financial returns in the long run.

Future Trends in Solvent Filter Trap Technology

The field of solvent filtration is continuously evolving, with advancements in materials, designs, and functionalities. Some of the emerging trends include:

- Smart filters with real-time monitoring capabilities

- Nanotechnology for enhanced filtration efficiency

- Integration with automated systems for streamlined operations

As technology progresses, solvent filter traps are likely to become even more sophisticated, offering greater precision and ease of use.

Conclusion

Solvent filter traps are indispensable tools in modern laboratories, ensuring the purity and reliability of solvents used in various processes. By understanding their types, applications, and maintenance requirements, laboratories can optimize their performance and achieve better outcomes.

We encourage readers to share their experiences and insights in the comments section below. Additionally, exploring other articles on our site can provide further knowledge and resources to enhance your laboratory practices. Together, let's advance the field of science and technology through innovation and collaboration.